Chemical Vapor Deposition System (CVD)

Chemical vapor deposition system (CVD) ,three-temperature zone CVD system, the diameter of the growth sample chamber is 60-120mm, which is composed of a high-temperature tube furnace, a multi-channel high-precision flow control and gas supply system, a mechanical pump, and a vacuum It is composed of sealing and measurement system and exhaust gas treatment system, and the ultimate vacuum degree can reach 10^-5 torr.

Main feature

1. The advantage lies in the preparation of thin film materials, low-dimensional nanomaterials, etc. (especially suitable for the growth and in-situ doping of transition metal two-dimensional semiconductor materials, as well as the growth of multi-dimensional two-dimensional materials)

2. An optional remote plasma radio frequency generation system can be used for plasma-assisted growth, etching processing and material surface modification of thin film materials, low-dimensional nanomaterials, etc. (especially suitable for the non-invasive treatment of two-dimensional materials such as graphene and boron nitride. Catalytic growth, defect control, and residual glue removal in the device manufacturing process)

3. The growth process design is advanced and can satisfy the non-catalytic growth of the substrate.

4. Application cases (click to jump)

| Temperature control parameters | unit | |

|---|---|---|

| temperature | 1200 | ℃ |

| power | 6.5 | kw |

| Temperature control accuracy | ±1 | ℃ |

| Vacuum system | ||

| Vacuum pump | 1 x 10 -3 (7.5 x 10 -4 ) | mbar (Torr) |

| Vacuum pump (open gas ballast) | 1.5 x 10 -2 (1.1 x 10 -2 ) | mbar (Torr) |

| Vacuum pump (use PEPE oil) | 1 x 10 -2 (7.5 x 10 -3 ) | mbar (Torr) |

| Vacuum degree inside the cavity | Better than 2.0 * 10 -2 | Torr |

| Flow control parameters | ||

| Leakage rate | 4×10 -9 | atm-cc/secHe |

| resolution | 0.1% of full scale | |

| Response time gas characteristics | < 2 | s |

| Response time electrical | 500 | ms |

| characteristics | ||

| Exhaust gas absorption parameters | ||

| Material | Shell aluminum alloy, stainless steel PTFE | |

| suction chamber | PTFE | |

| Plasma system parameters | ||

| Power output | 5 – 300, 5 – 500 | W |

| Signal frequency | 13.56 ±0.005% | MHz |

| Reflected power | 200 | W |

| Power stability | ±0.1% | |

| harmonic components | ≤-50 | dbc |

| Supply voltage | Frequency 50/60HZ |

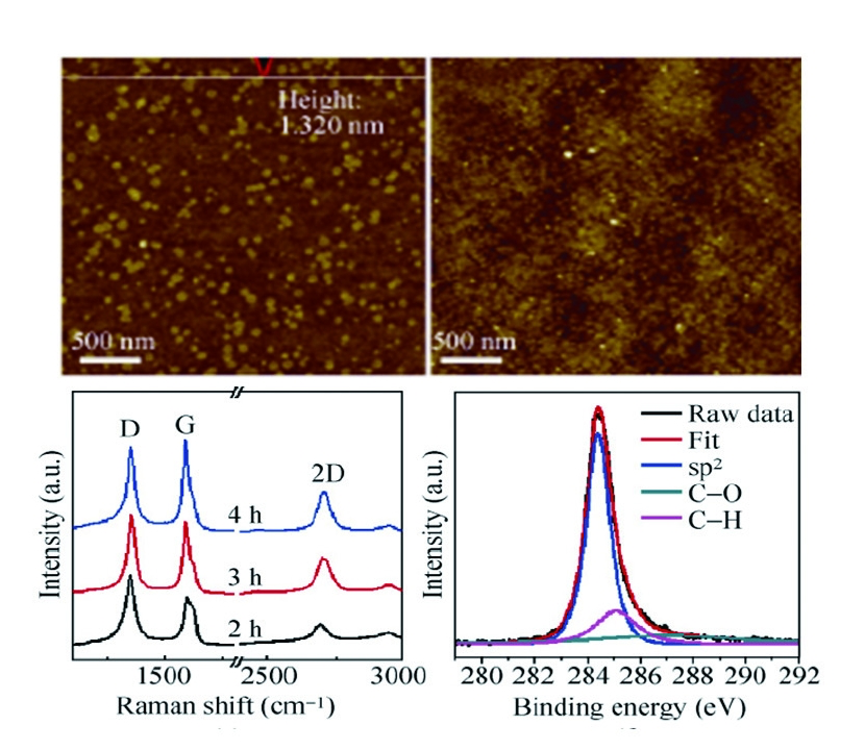

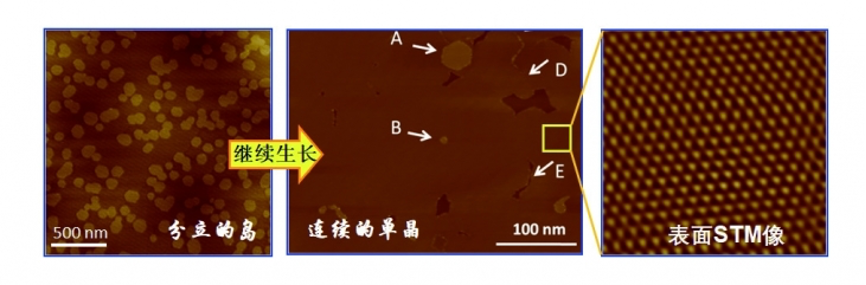

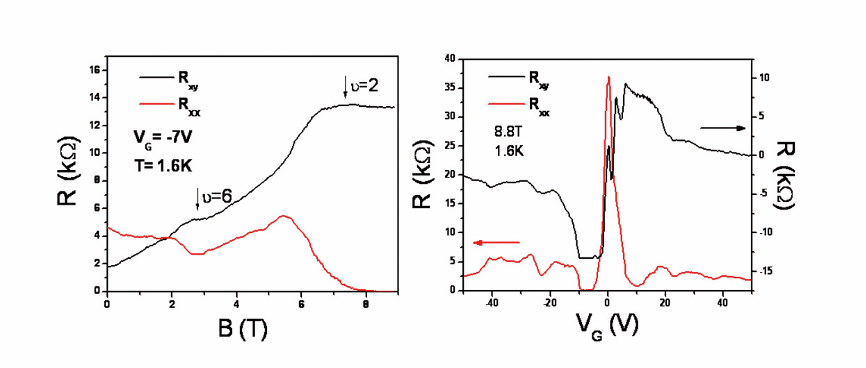

- Catalytic-free growth of Graphene on any substrate

-

- Catalytic-free epitaxial growth of Graphene

-

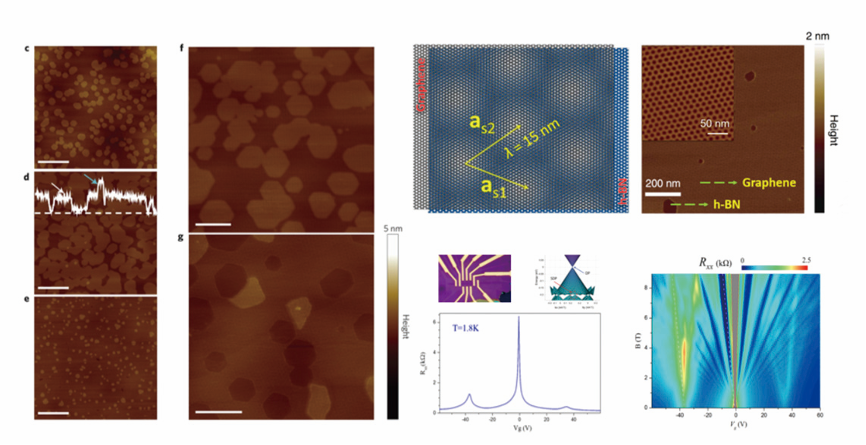

- Epitaxial Graphene/BN heterojunction and Moiré superlattice

-

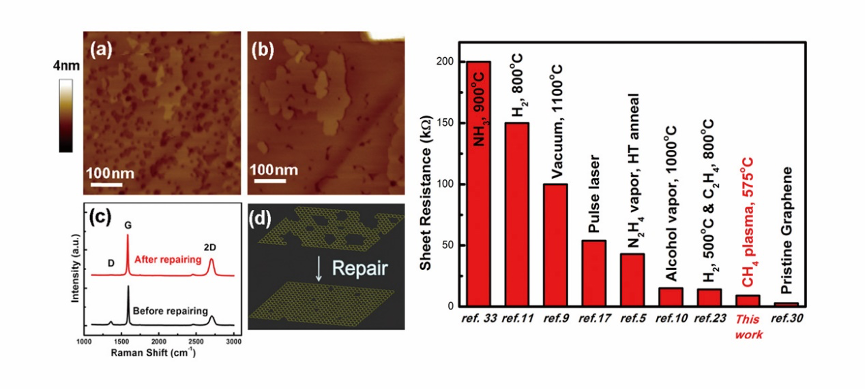

- EDefect repair of graphene oxide

-

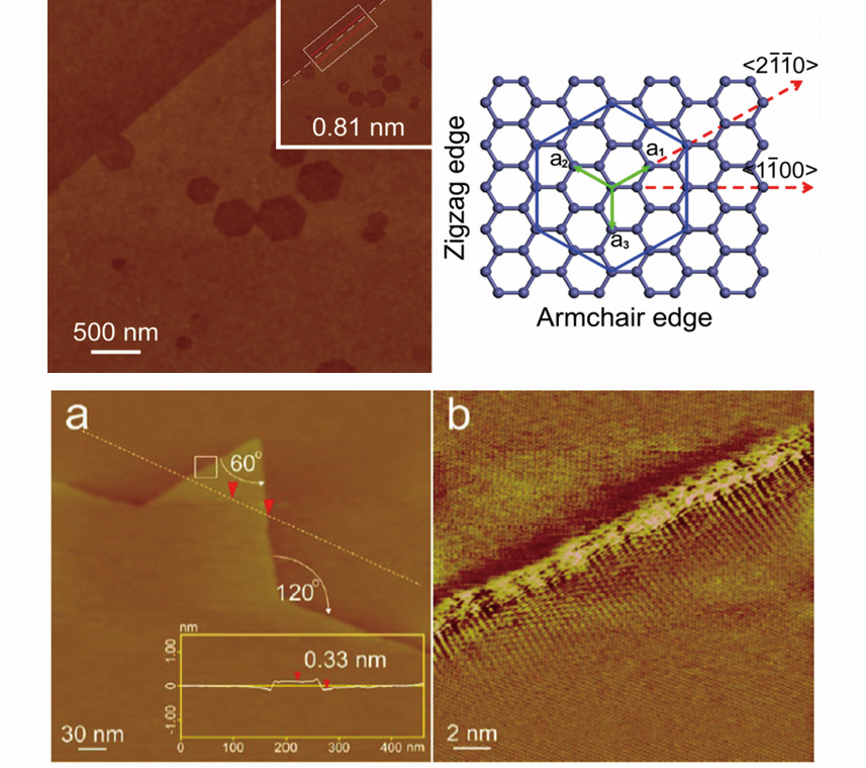

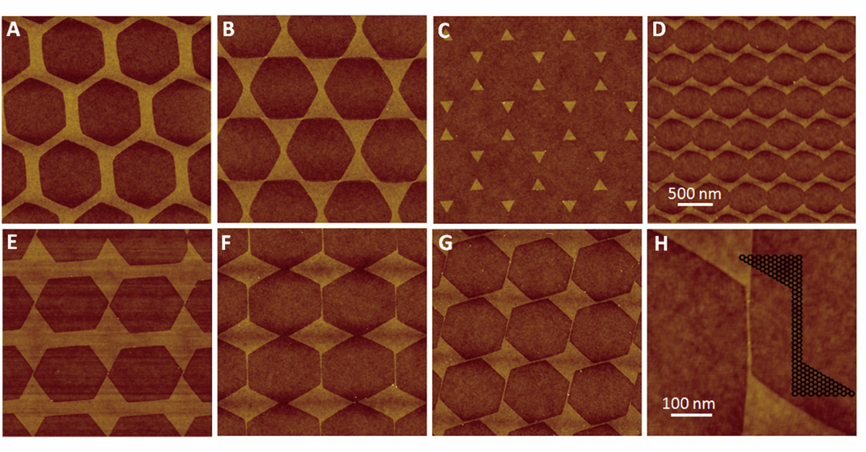

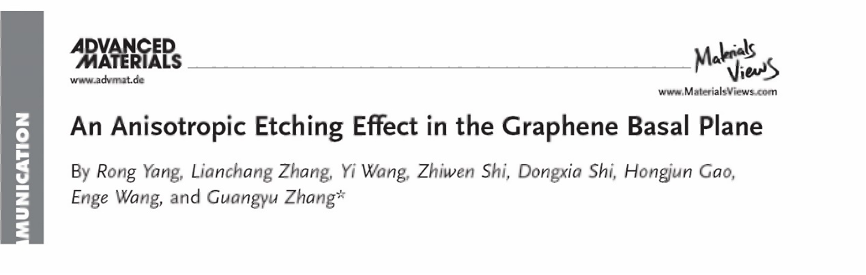

- Development of Graphene’s Anisotropic Etching Technology

-

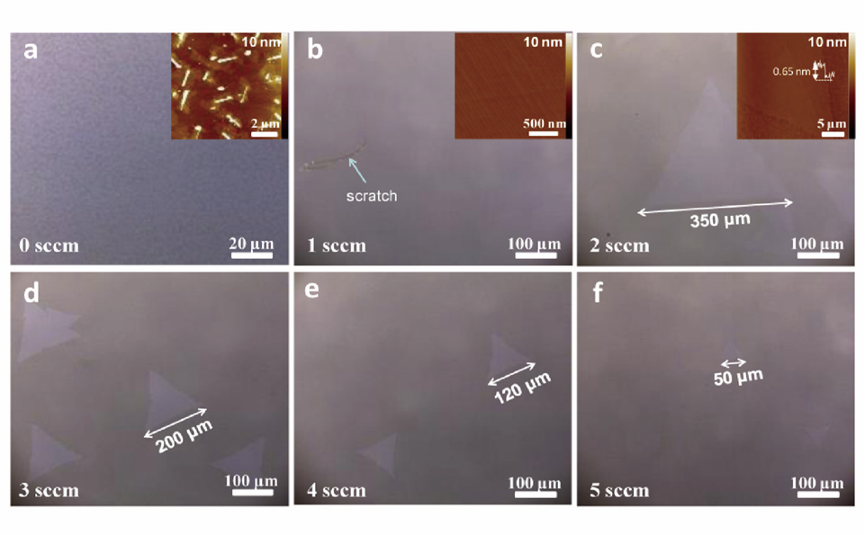

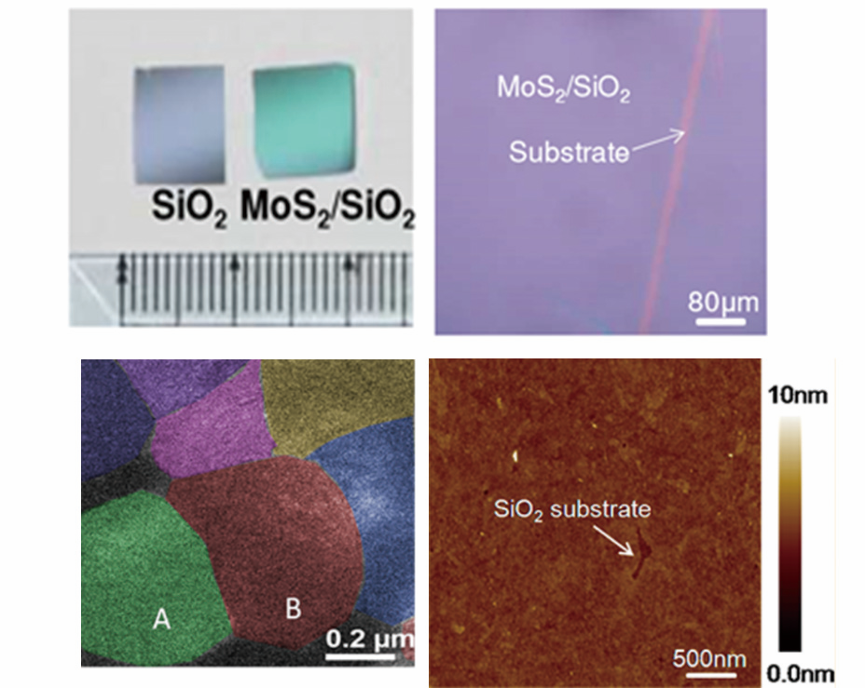

- Controlled growth and grain size adjustment of MoS2

-

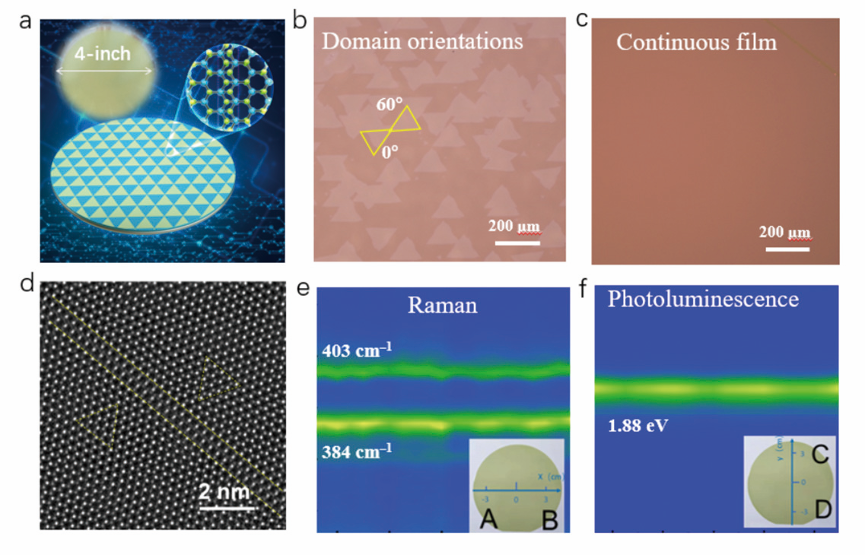

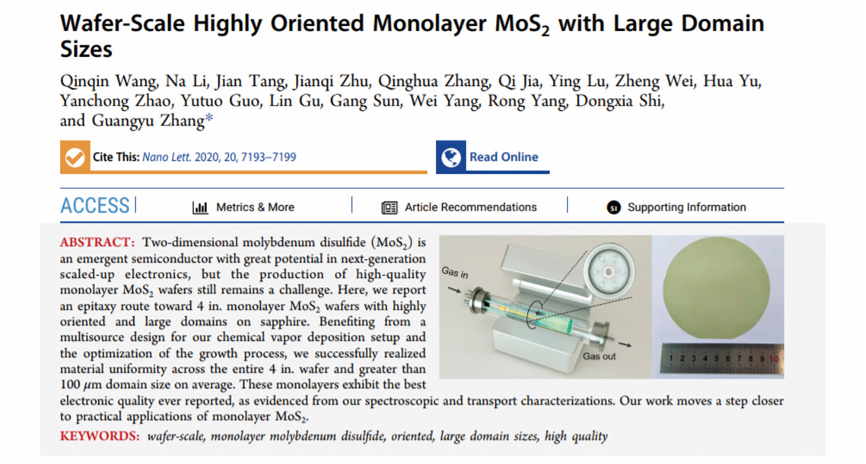

- Oriented epitaxial growth of two/four-inch continuous monolayer MoS2

-